Our Blog

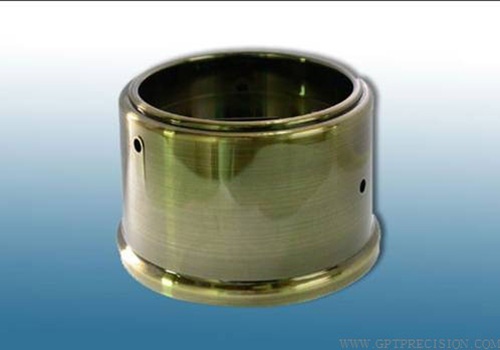

Cold Runner Nozzle Tips&Bushing With Stainless Steel

Description: Precision Turning Part Material :1.2379 Heat Treatment: Quenching Hardness: 60~62HRC Accuracy: ± 0.001MM Tooling Process:Roughing Turning -gun drilling-tapping-Quenching-fine tunning-Mirror EDM-Slow Wire cutting-Cylinder Grinding-cleaning-Inspection-Packing;

High Precision Mold Inserts for Injection ,Diecasting and Stamping

Description: Precision Turning Part Material :1.17131 Heat Treatment: case hardened Hardness: 56~58HRC Accuracy: ± 0.01MM Tooling Process:fine turning -Quenching–cleaning-Inspectio n-Packing;

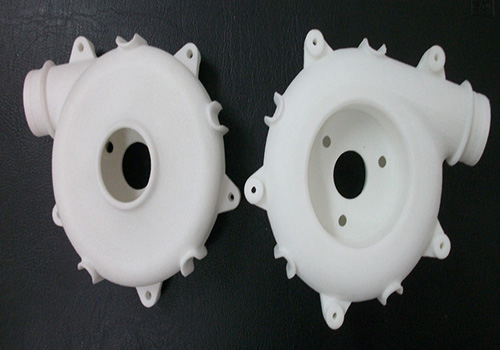

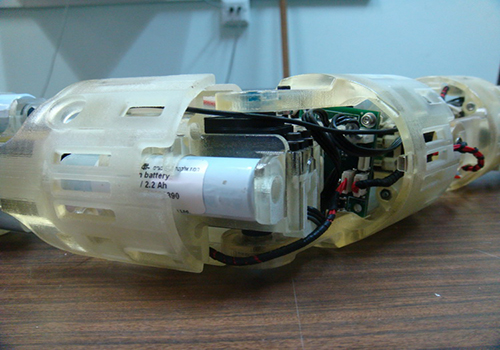

3D Printing Industrial Prototypes

Selective Laser Sintering (SLS) The use of selective laser sintering prototyping (commonly called SLS prototyping or 3D SLS prototyping) is ideal for product prototypes that require exceptional strength or must closely approximate the properties of thermoplastics. In (SLS), three-dimensional parts are created by fusing (“sintering”) powdered thermoplastic materials such as nylon, metals, and elastomers with the heat from an infrared …

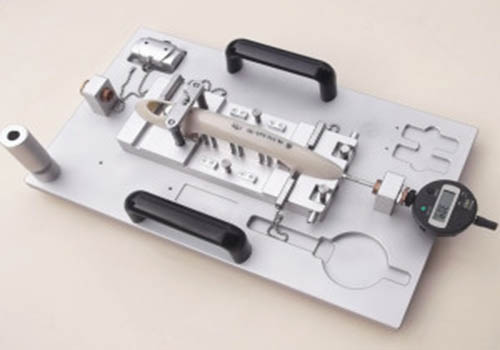

Mass Production Solution for High-Precision Parts

Mass production is the manufacturing of large quantities of standardized products, often using assembly lines or automation technology. Mass production facilitates the efficient production of a large number of similar products. Mass production is also referred to as flow production, repetitive flow production, series production, or serial production. In mass production, mechanization is used to achieve high volume, detailed organization …

How to Achieve the Expected Accuracy Goals in Machining

In the realm of manufacturing, particularly in machining, achieving the desired level of accuracy is paramount. Whether it’s crafting intricate components for aerospace technology or producing precise parts for medical devices, the demand for accuracy is universal. However, attaining these accuracy goals requires a combination of technical expertise, advanced machinery, meticulous planning, and continuous improvement strategies. So, how do manufacturers …